รายละเอียดสินค้า:

การชำระเงิน:

|

| Laser power: | 500W ( other power can be optional ) | Max. speed of the table: | 100mm/s |

|---|---|---|---|

| Z axis adjustment: | Manually or serov motor linkage CCD monitoring system | Positioning accuracy: | 0.05mm |

| Repeat positioning accuracy: | 0.02mm | Cooling: | Water cooling |

| Pulse width: | 0.1~50.0ms | Power supply requirement: | 380V±10%,50Hz,40A |

| Electricity requirement: | 12-15kW,three phase | Power feedback loop: | Energy feedback system |

| แสงสูง: | fiber welding machine,laser welding equipment |

||

Solar Panel Fiber Laser Welding Machine with 2 Laser Welding Heads

1, Machine main features

1.1. With automatic translation table to fulfill large format spot welding, implementing online spot welding, fast speed, flexible processing.

1.2. Machine optic system use the fiber transmission instead of the mirrors reflect which has low future failure rate and high electro-optic conversation.

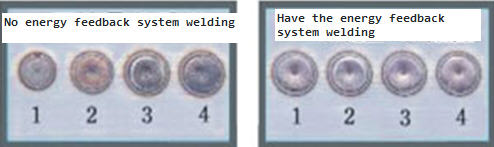

1.3. Industry-leading "energy negative feedback" will shock optical output power fluctuation control in less than 3%, to ensure that the laser stable power output, thereby improving welding stability, the advantages of the energy feedback, pls check the below comparations:

1.4. Cooperating with the relevant fixtures, within the scope of the 2-3 axis working table which can realize automatic welding , capable of carrying multi-axis linkage control system, realize the complex graphics continuous automatic welding.

1.6. Can realize double light paths, such as four light path multipass spectroscopy, by spectral energy spectral and time, not only can realize the double location processing, saves the material, up and down time, greatly improve prodcution efficiency, can realize multiple perspectives of multipass welding at the same time more complex processing requirements.

1.7. Welding quality: solder joint is smooth and beautiful, smooth and no welds holes, welding, toughness, at least equal or exceeding base metal without treatment or need only a simple processing after welding Management, reduce labor intensity;

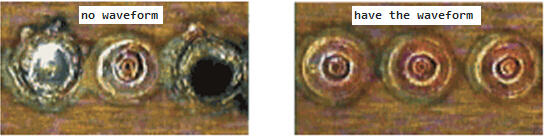

1.8. Our fiber laser welding machine has the waveform control, so it ensure the each laser dot output is very stable and uniform, the below is the comparation between machine have the waveform control and without waveform control

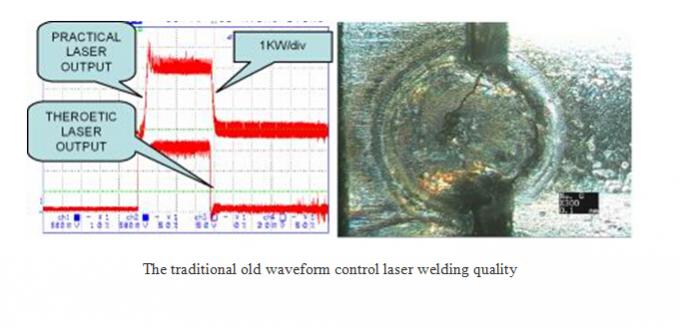

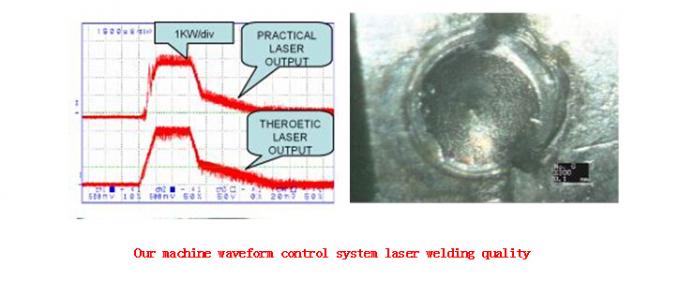

1.9. the compare between our patent waveform control systam and the traditional waveform machine

2, Machine's application fields

Our fiber laser welding machine is widely used in solar panel industrial .

3, Machine's application materials

The stailnless steel, plain carbon steel, alloy steel,iron, stainless steel, low carbon steel, steel -310 316 stainless steel, alloy steel and 347 nickel, different levels of nickel, titanium, nickel, tin, copper, aluminium, niobium, gold, silver of metal or alloy the same metal for the welding. copper and nickel, titanium, copper and nickel, titanium, titanium, molybdenum, brass, copper, and low carbon steel, copper, metal for the welding.

4, Machine main technical parameters

|

Model |

ST-P500-SP |

|

Wavelength |

1064nm |

|

Pump sources |

Two Xe-lamp (imported), Gold plating chamber |

|

Max.power |

300W |

|

Max. single pulse energy |

60J |

|

Pulse width |

0.1~50.0ms |

|

Sequency frequency |

1~200Hz |

|

Welding spot size |

0.2~1.5mm |

|

Welding depth |

0.1~3.0mm |

|

Sequence welding |

15mm/s |

|

Observe system |

CCD monitor |

|

Positioning |

Red light indication |

|

Cooling system |

Water cooling |

|

Repeatability precision |

0.02-0.05mm |

|

Machine size |

770mm*1350mm*1200mm (L*W*H) |

|

Water chiller size |

600 * 880 *1450 mm |

|

Electricity requirement |

12-15kW,three phase |

|

Power supply requirement |

380V±10%,50Hz,40A |

|

Machine total Gross weight (KG) |

420KG |

|

|

Laser generator : 850mm*1500mm*1250mm |

5, The laser welding working table for solar panel explanations

5.1. The Solar panel laser welding machine is a duplex structure of two-dimensional laser welding head laser welding workstations, laser welding head can automatically rotate station for solar panels laterally, longitudinally welded

5.2. PC control, to meet an array of point products, straight path welding, welding track the use of CNC programming input

5.3. X, Y axis servo motor drive, using high-precision ball screw and ball rail transmission, X-axis stroke of 2350mm, Y-axis stroke of 1100mm, repeat positioning accuracy of 0.05mm .

5.4. Base and are used to measure the box structure, work platform precision casting, after annealing aging treatment, aging, such as multiple vibration to eliminate stress, to ensure that no deformation

6, The laser welding samples photo