รายละเอียดสินค้า:

การชำระเงิน:

|

| Product name: | Fiber laser cutter | Effective Cutting size: | 1500 * 3000mm (1300 * 2500mm optional ) |

|---|---|---|---|

| Real laser power: | 500 W | Laser wavelength: | 1064nm |

| Laser type: | Fiber | Power consumption: | 10 KW |

| Focus system: | Automatic following and detective | Power supply: | Three Phase 380V/50Hz |

| Processing material: | stainless steel, carbon steel, Aluminum, etc | ||

| แสงสูง: | fiber laser cutting equipment,fiber optic laser cutting system |

||

Fiber laser cutter of power 500W for metals cutting 380V / 50HZ

Description

1. Machine has the home-grown Automatic tracking system, anti-collision design, automatically adjust the best focus, the best machine frame structure adopts box-structure, plate welding structure, with outstanding advantage of year-round using with no deformation.

2. It adopts the world’s top quality fiber laser source and patent technology, stable performance, the lifetime of the key parts could reach 100,000 hours, fiber transmission and high electro- optical conversion rate , no need the reflect lens, save much future maintenance cost .

3. Machine use the fiber transmission, flexible processes, suitable for stainless steel, carbon steel and other materials, X, Y, Z axes are imported from Japan servo motor, high-precision, high- speed, high-torque, high inertia, stable performance and durable. Ensure the machine's high speed and acceleration.

4. Top high end performance achieved to realize ultra-high precision processing requirements, automatic following system, China top viability, can realize a calibration, automatic following.

5, Imported high - precision electronic control proportional valve, precise control of the cutting auxiliary gas pressure, in order to achieve the best cutting results , the machine uses a moving gantry structure, imported high-precision screw and linear guide, smooth transmission, high precision.

6, The bed sheets use welded structure and the beam used the whole casting, aluminum structure, which have a constant in highlighing the advantages of using without distortion, free running speed: null shift speed can be up to 60m/min.

7. Performantion in advanced mode, the plate quickly punch cutting, cutting time saved, leading the cutting process, which can meet all kinds of shapes precise cutting, such as: 4mm thick carbon steel can be achieved 2mm diameter hole cutting.

8. fast cutting speed, 1mm stainless steel the Max. cutting speed is 10 meters/Min .

Aplication materials

Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet and other metal pipes and tubes.

Applicable Industry

It is widely applied in industrial pipeline processing, explosion-proof equipment, military industry, chemical industry, oil exploration, lamps and lanterns, metal processing, ironware, building, etc.

The machine’s main structures

The machine consists of machine tool, fiber laser source, the CNC control cabinet, the water chiller, the CNC control system

A). Technical specifications:

|

Optical parameter |

Unit |

500W |

|

Running mode |

CW, QCW |

|

|

Center radiation wavelength |

Nm |

1070-1080 |

|

Standard output power |

W |

500 |

|

Beam quality |

Mm*mrad |

4 |

|

Adjusting speed |

Khz |

5 |

|

Transmission fiber diameter |

Um |

≥50 |

|

Output power stability |

﹪ |

±2 |

|

Power |

VAC |

400-460 |

|

Power consumption |

KW |

2 |

B). System structures

|

No. |

Description |

Qty |

Remarks |

|

1 |

Optical system speed expansion lens focusing lens spectroscope |

1 |

Adopt the Germany technology and special designed, optical lens directly affect the quality of facular, the affect the quality of cutting seam and flange, cutting speed and the cutting thickness |

|

2 |

Japan Panasonic servo motor |

2 |

Adopt the high precision Panasonic servo motors and the corresponding driver, imported screw and rails from Taiwan HIWIN famous brand. |

|

3 |

Fiber laser source |

1 |

Original Germany IPG or the China A top quality Raycus ( optional ) |

|

4 |

Control system |

1 |

Industrial PC, high temperature resistance and more stability |

|

5 |

Advanced cutting Software |

1 |

CYPCUT (You can easily achieve a high degree of automatic tracking, segmentation perforation, perforation progressive, cutting edge finder, leapfrog elevation, elevation of the cutting head arbitrarily set, light path compensation |

The machine’s main technical parameters

|

Specifications |

Parameters |

|

Max. laser power |

500W |

|

Laser wavelength |

1064nm |

|

Effective processing area |

1500*3000mm(other size can be customized ) |

|

Positioning |

Red light indication |

|

X,Y axis repeat positioning precision |

±0.03mm |

|

X/Y axis positioning accuracy |

0.05mm/m |

|

Z axis route |

120mm |

|

X/Y max axial acceleration |

1G |

|

Max. loading weight |

500KG |

|

Protection level of main power |

IP54 |

|

Max. cutting thickness |

≤6mm ( the real thickness depend on the actual materials ) |

|

Cutting software Support format |

DXF and PLT which outputted from the Auto CAD or CorelDraw software ) |

|

Total power consumed |

≤10KW |

|

Power supply |

3 phases , 4 wires AC, 380V, 50HZ/60HZ/60A |

|

The Auxiliary gas |

O2 , N2 and compressed air |

|

Machine whole weight |

2800KG |

|

Machine loading method |

40 feet container |

Machine’s main configurations

|

Item |

Name |

Specifications |

Qty |

|

1 |

QL-FC3015 |

3000*1500mm |

1 set |

|

2 |

Fiber laser source |

500W |

1 |

|

3 |

CNC control system |

LASERCUT&CYPCUT |

1 |

|

4 |

Laser cutting head |

Patent products ( USA technology ) |

1 |

|

5 |

Water chiller |

Wuhan China |

1 |

The spare parts free provided from supplier

※ Protection lens 2 pieces

※ Nozzle 2 pieces

※ Allen wrench 1 set

※ Cleaning paper 1 set

※ User menu 1 set

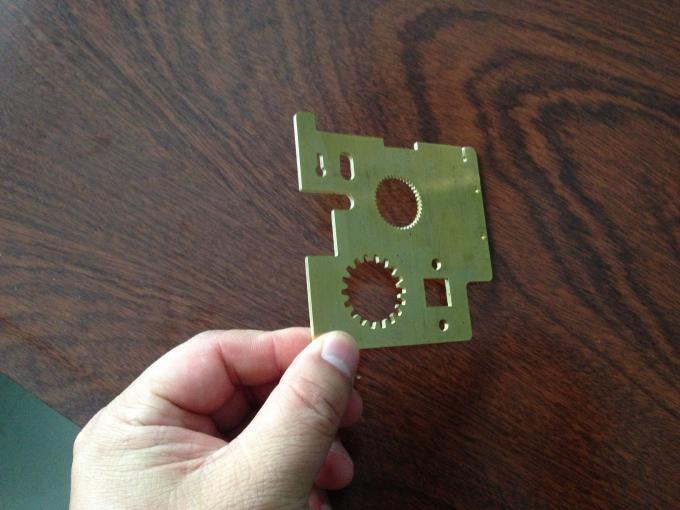

The cutting samples photos as follows: